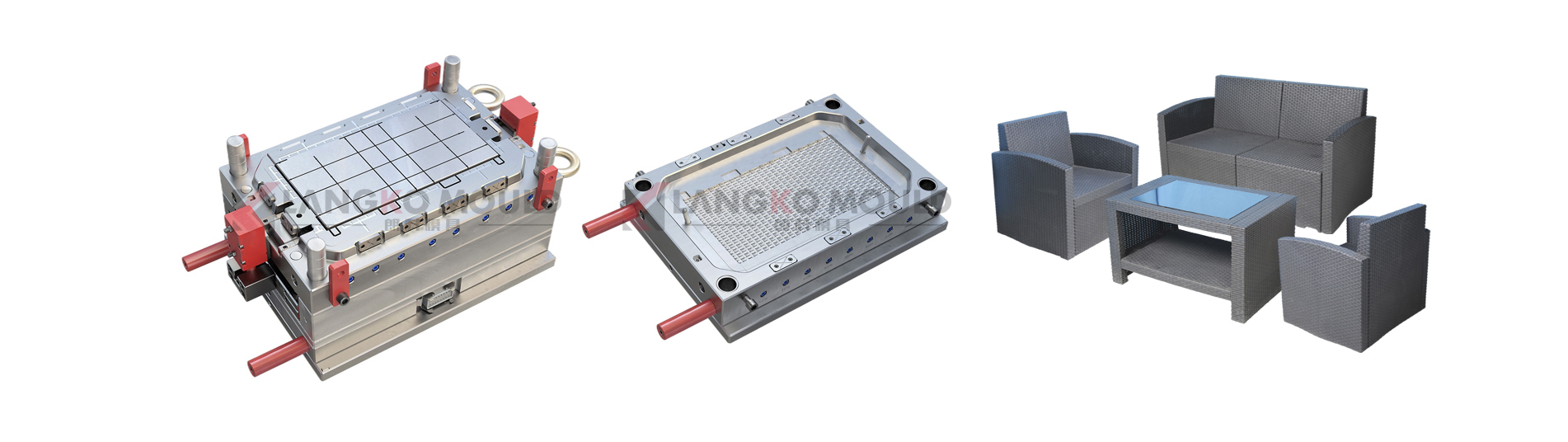

Plastic injection PP/HDPE pallet mold huangyan mould maker

栏目:MOULD BLOG 发布时间:2025-06-30

In the logistics industry, pallet is indispensable handling and storage tools, and their quality and performance directly affect logistics efficiency. Pallet mold, as key equipment for producing pallets, play a decisive role in the quality of pallets. Please check out this blog to learn more about pallet mold.

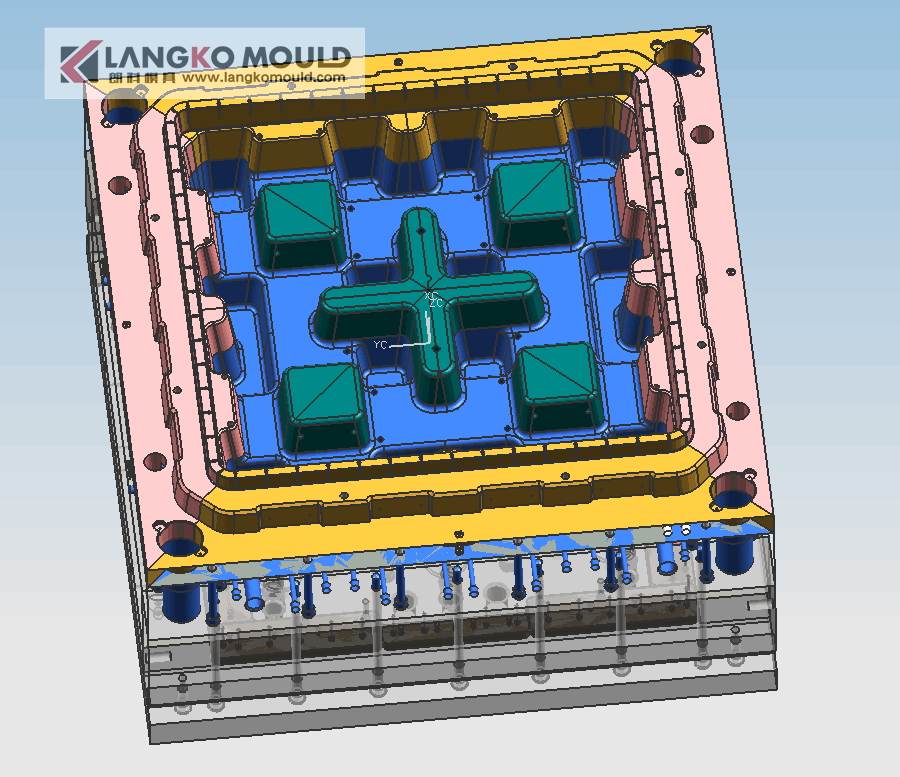

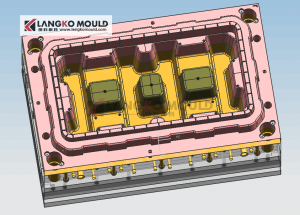

1. Design of pallet mold

Dimensional accuracy and stability: Pallets need to adapt to various logistics equipment and scenarios, so the mold design must ensure high precision of the pallet size. Whether it is length, width or height, the tolerance range must be strictly controlled to ensure the versatility and interchangeability of the pallet on different equipment. At the same time, the mold structure must have good stability and be able to withstand high pressure and high temperature during the injection molding process to avoid pallet size deviation due to mold deformation.

Structural strength optimization: Considering that the pallet needs to carry goods of different weights during use, the mold design should focus on the structural strength of the pallet. By rationally designing the pallet's rib layout, thickness distribution, and connection method, the pallet's load-bearing capacity and anti-deformation ability can be improved.

Demolding convenience: In order to improve production efficiency, the mold design must ensure that the tray can be demoulded smoothly. This requires reasonable design of the demoulding slope, demoulding mechanism and cooling system.

2. The influence of injection molding process on pallet quality

Selection of plastic materials: Different plastic materials have different performance characteristics, such as strength, toughness, corrosion resistance, etc. When producing pallets, it is necessary to select suitable plastic materials according to the use environment and load requirements of the pallet. Common pallet materials are HDPE and PP, which can meet the use requirements of pallets in various logistics scenarios.

Control of injection molding parameters: Parameters such as temperature, pressure and injection speed during the injection molding process have an important influence on the quality of the pallet. Too high temperature may cause the plastic material to decompose and discolor, affecting the performance and appearance of the pallet; too low temperature may cause poor fluidity of the plastic, unable to fill the mold cavity, resulting in defects such as lack of material. Excessive pressure may cause the pallet to have problems such as flash and deformation; too low pressure may cause the pallet to have insufficient density and strength. Too fast injection speed may cause turbulence in the plastic in the mold, forming defects such as air marks and weld marks; too slow injection speed may cause the filling time to be too long, affecting production efficiency. Therefore, it is necessary to accurately control the injection molding parameters to ensure the stable quality of the pallet.

3.Advantages of pallet mold

Efficient production:Pallet Injection molds have high production efficiency and can produce a product in 2-3 minutes. Injection molding can greatly shorten the production cycle and meet the market's large demand for pallets.

Stable quality: The pallets produced by the mold have high dimensional accuracy and stable quality. The standardized production of the mold can ensure that the quality of each pallet meets the design requirements, reduce the fluctuation of product quality, and improve the reliability of logistics operations.

Customization capability: We can design and manufacture pallet molds of various specifications, shapes and functions according to the different needs of customers.

Cost-effectiveness: The mold has a long service life and can be reused many times, further improving cost-effectiveness.

Pallet mold play an important role in the logistics industry. Through reasonable design, precise injection molding process control and the advantages of the mold itself, high-quality and high-performance pallets can be produced, providing strong support for the efficient operation of the logistics industry. If you have any needs or questions about pallet molds, please feel free to contact us, we will wholeheartedly provide you with professional solutions and quality services.

86-0576-81122860

86-0576-81122860